Australian surfwear manufacturer Billabong halved production time for print catalogues after implementing Typefi publishing automation software.

Founded on Australia’s Gold Coast in 1973 by surfer and surfboard shaper Gordon Merchant and his then partner, Billabong has grown from a local producer of quality handmade boardshorts to one of the world’s most recognised surfwear brands.

Throughout its ongoing growth and international success, Billabong has upheld its brand integrity, continuing to produce and sell high-quality retail goods and maintaining a strong commitment to the global boardsports sector (surf, snow and wake) through athlete sponsorship, event hosting, and management and support of industry bodies.

Billabong’s head office is on the Gold Coast in Queensland, Australia, with branch offices located all over the world.

The challenge: Speeding up catalogue production while maintaining accuracy

In 2008, sales catalogues were produced locally in each region, with the Gold Coast office managing publishing for Australia and New Zealand.

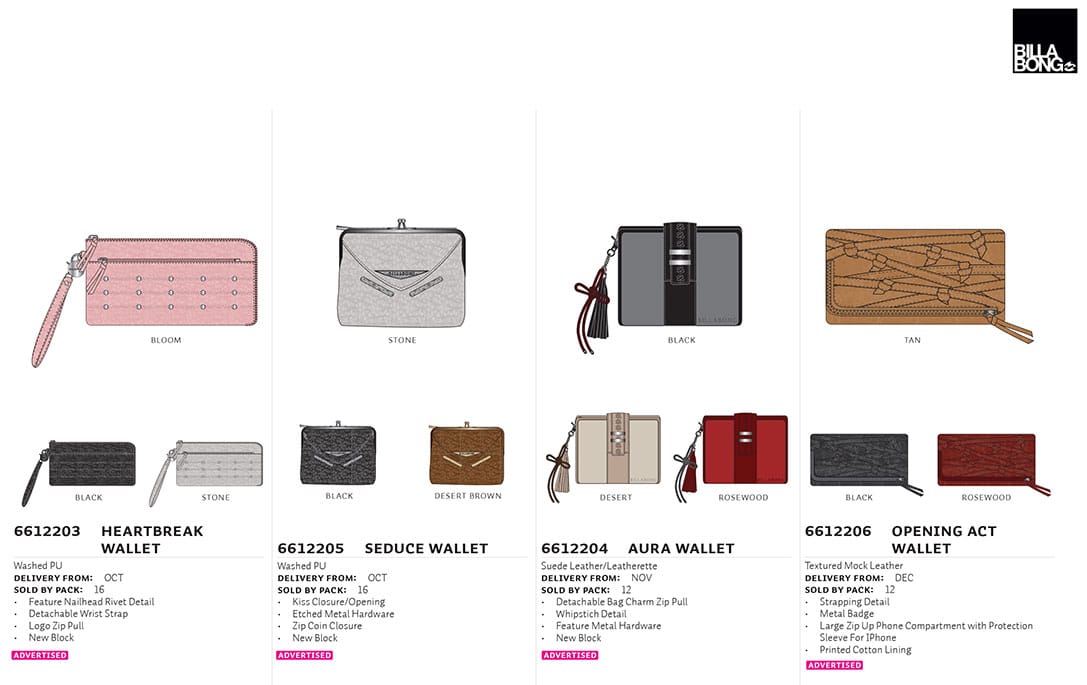

The Gold Coast team produced three series of print catalogues per year in-line with seasonal range releases. Four separate catalogues for the Men’s and Women’s Garment and Accessories collections were produced for each seasonal release.

The detailed product information and images contained in Billabong’s catalogues was managed in a centralised product database. The data hierarchy was fixed, with product content organised into specific fields.

To produce the catalogues, the production team performed a data merge from the centralised product database into Microsoft Excel, and then imported the Excel data into Adobe InDesign for in-house graphic designers to lay out.

As Billabong’s product data changed with reasonable frequency during catalogue production cycles, the team found the established publishing process inflexible and prone to errors.

The product data could only be imported into InDesign once, with designers then spending considerable time manually applying layout and styles.

It was very difficult to make substantive, but essential, changes to the copy, such as removing a discontinued product, adding a new product, or changing the order for product listings. Seemingly minor changes created flow-on effects that could be extremely time-consuming.

As sales and orders were made from the catalogues, it was also imperative that the product data was 100% accurate. The manual updating process was prone to error and required many proof corrections to manage changes in core data.

The solution: Separating product data from catalogue design

Billabong’s production team implemented Typefi in 2008 to automate catalogue composition, which enabled a faster and more efficient publishing workflow.

While product data and images continued to be managed from Billabong’s centralised database, designers worked separately in Adobe InDesign to build the catalogue templates required for each seasonal release.

When content was ready to publish, Typefi automatically populated the pre-prepared design templates with the most up-to-date catalogue data, rendering it as an InDesign file for layout modifications, or as a PDF for proofing and printing.

By 2009, print proofs were available in half the time—from an average of two weeks down to within a week—and the turnaround time on changes to the proofs was also much shorter.

Rhonda Saunders, Project Manager at Billabong, explained that separating product data management from catalogue composition had significant production benefits.

“Typefi has helped us reduce catalogue production timelines and reliance on graphic designers to carry out catalogue composition,” she said.

Improved accuracy and faster production cycles, even for last-minute product updates

As well as delivering speedier production turnaround and increased accuracy, Typefi introduced far greater flexibility into Billabong’s publishing workflow.

If product information changed prior to publication, the data was simply run through Typefi again to generate a new InDesign file for proofing.

This meant that catalogue data could be updated with efficiency and accuracy, keeping the production team right up to date with sales, marketing and design changes and minimising the potential for introducing errors to content during the design process.

“It is so much easier to make significant changes at any stage, like rearranging the order of content or making essential product updates,” Rhonda Saunders said.

“Typefi has delivered the benefits we hoped for—improved accuracy and faster production times.”

Ready to take the first step towards revolutionising your publishing?

We’ll work with you to understand the publishing challenges you’re facing and determine which Typefi solution best suits your budget and production requirements. Start by telling us a bit about your publishing needs and we’ll be in touch!